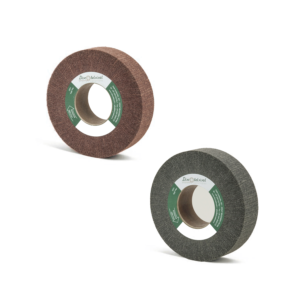

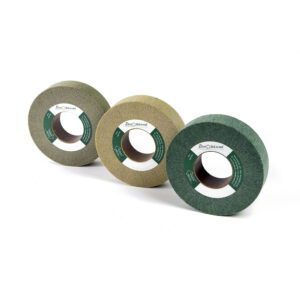

NWF FLAP WHEELS

They are composed of strips of abrasive “non-woven fabric” glued radially around a core. They are manufactured in various grains and hardnesses, using either “non-woven fabric” with aluminium oxide or silicon carbide. They are available in different formats and can be used manually on portable machines or on automatic machines or robots. NWF flap wheels are built in long rolls and then cut to the required thicknesses.

They can be used both on flat and shaped surfaces, adapting perfectly to the shape of the profile. The sanding units that mount these wheels are usually equipped with variable speed and selectable direction of rotation. The long rolls are used on machinery for the processing of coils or metal plates or in the processing of solid wood, chipboard or MDF panels.

ADVANTAGES

- They can work in both directions of rotation

- They can be shaped to perfectly fit the shape of the product to be processed

- The abrasive regenerates automatically during processing, maintaining a constant cutting and finishing capacity

- They can be used in sequence with different combinations of grains

- They can be manufactured with different hardnesses according to the surface to be treated

APPLICATIONS

- Wood sanding

- MDF sanding

- Paint buffing

- Metal satin-finishing

- Welding cleaning

- PCB surface oxidation removal

- Ceramic tiles lapping

- Removal of glaze on tile edges